Olympus

The large, full VGA transflective display combined with our patented digital high dynamic range receiver provides a stable, striking A-scan representation in any lighting condition. The EPOCH 650 is designed to meet the requirements of ISO 22232-1 and allows a full range of standard and optional flaw detection features. Multiple onboard reporting tools and a comprehensive data filing system enable you to easily collect and report high quality inspection data. The rugged, ergonomic design allows use in nearly any inspection environment, while the flexible PerfectSquare pulser and highest number of digital filters in its class can tackle nearly any application.

The EPOCH 650 Digital Ultrasonic Flaw Detector combines Olympus’ industry leading conventional flaw detection capabilities with the efficiency of a highly portable, intuitive instrument. The EPOCH 650 flaw detector’s blend of efficient menus and direct access keys allows you to take advantage of the highest quality flaw detection platform with exceptional ease of use.

The EPOCH 650 is designed for use in nearly any inspection environment, from bench top testing in a laboratory to extreme outdoor and hazardous conditions. Designed for IP rating in either knob (IP66) or navigation pad (IP67) configurations, and tested to very high environmental and reliability standards, the EPOCH 650 allows users in any inspection environment to feel confident in both the performance and durability of the instrument.

Key Features

Designed to meet the requirements of ISO 22232-1

PerfectSquareTM tunable square wave pulser

Full screen A-scan mode

Digital high dynamic range receiver

Thirty digital filters for enhanced signal-to-noise ratio

2 kHz PRF for rapid scanning

Knob or navigation pad adjustment configurations

Large, full VGA sunlight readable display

15 hours of battery life

Standard dynamic DAC/TCG and onboard DGS/AVG

Multiple on-board report formats

MicroSD memory card for data transfers

Optional Corrosion Module software with Encoded B-scan

USB On-The-Go (OTG) for PC communication

Alarm and VGA outputs

Optional analog output

SPECS :

Instrument Inputs/Outputs

USB Ports USB On-The-Go (OTG)

RS-232 Port Yes

Video Output VGA output standard

Analog Output 1 analog output (optional), Selectable 1 V/10 V Full Scale, 4mA max

Alarm Output 3 alarm outputs, 5 V TTL, 10 mA

Trigger I/O Trigger input, 5V TTL;

Trigger output, 5V TTL, 10 mA max

Encoder Inputs 1-axis encoder line (quadrature - Corrosion Module mode only)

Environmental Ratings

IP Rating

Designed to meet the standards of the Ingress Protection (IP) rating number IP67 (navigation pad version) or IP66 (knob version) per IEC 60529-2004 (Degrees of Protection provided by enclosures – IP Code).

The product design was confirmed to meet the IP rating by means of Olympus internal design verification test process that occurs prior to the release of the product to production.

Explosive Atmosphere

Safe operation as defined by Class I, Division 2, Group D, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810F, Method 511.4, Procedure I.

Shock Tested

MIL-STD-810F, Method 516.5 Procedure I, 6 cycles each axis, 15g, 11 ms half sine.

Vibration Tested

MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis

Operating Temperature

–10 °C to 50 °C (14 °F to 122 °F)

Battery Storage Temperature

0 °C to 50 °C (32 °F to 122 °F)

General

Overall dimensions (W x H x D) 236 mm x 167 mm x 70 mm (9.3 in. x 6.57 in. x 2.76 in.)

Weight 1.6 kg (3.5 lb), including lithium-ion battery

Keypad English, International, Japanese, Chinese

Languages English, Spanish, French, German, Japanese, Chinese, Portuguese, Russian

Transducer connections BNC or Number 1 LEMO

Data storage 100,000 IDs onboard, removable 2 GB MicroSD card (standard)

Battery type Single lithium-ion rechargeable standard

Battery life 15 h to 16 h (lithium-ion)

Power requirements AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 HZ to 60 Hz

Display type Full VGA (640 x 480 pixels) transflective color LCD, 60 Hz update rate

Display dimensions (W x H, Diag.) 117 mm x 89 mm, 146 mm (4.62 in. x 3.49 in., 5.76 in.)

Receiver

Gain 0 to 110 dB

Maximum input signal 20 V p-p

Receiver input impedance 400 Ω ± 5%

Receiver bandwidth 0.2 MHz to 26.5 MHz at -3 dB

Digital filter settings Thirty digital filter sets standard

Seven ISO 22232-1:2020 compliant filters (0.2-10 MHz, 2.0-21.5 MHz, 8.0-26.5 MHz, 0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz)

Rectification Full-wave, Positive Half-wave, Negative Half-wave, RF

System linearity Horizontal: ± 0.5% FSW

Resolution 0.25% FSH, amplifier accuracy ± 1dB

Reject 0 to 80% FSH with Visual Warning

Amplitude measurement 0 to 110% full screen height with 0.25% resolution

Measurement rate Equivalent to PRF in all modes

Calibration

Automated calibration Velocity, Zero Offset

Straight Beam (First Backwall or Echo-to-Echo)

Angle Beam (Soundpath or Depth)

Test modes Pulse Echo, Dual, or Through Transmission

Units Millimeters, inches, or microseconds

Range 3.36 mm to 13,388 mm (0.132 in. to 527.10 in.) @ 5,900 m/s (0.2320 in./μ)

Velocity 635 m/s to 15240 m/s (0.0250 in./µs to 0.6000 in./µs)

Zero offset 0 µs to 750 µs

Display delay -59 mm to 13,401 mm (-2.320 in. to 526.97 in.) @ longitudinal velocity in steel

Refracted angle 0° to 90° in 0.1° increments

Gates

Measurement gates 2 fully independent gates for amplitude and TOF measurements

Gate start Variable over entire displayed range

Gate width Variable from Gate Start to end of displayed range

Gate height Variable from 2 to 95% full screen height

Alarms Positive and Negative Threshold, Minimum Depth (Gate 1 and Gate 2)

Measurements

Measurement display locations 5 locations available (manual or auto selection)

Gate (1, 2) Thickness, Soundpath, Projection, Depth, Amplitude, Time-Of-Flight, Min./Max. Depth, Min./Max. Amplitude

Echo-to-Echo Standard Gate 2-Gate 1, Optional IF Gate Tracking

Other measurements Overshoot (dB) value for DGS/AVG, ERS (equivalent reflector size) for DGS/AVG, AWS D1.1/D1.5 A, B, C and D values, Reject Value, Echo to RefdB values

DAC/TCG Standard

DAC points Up to 50 points, 110 dB dynamic range

Special DAC modes Custom DAC (up to 6 curves), 20-80% View

Curved surface correction Standard OD or Bar correction for Angle Beam measurements

Corrosion (optional) Zero-cross measurement algorithm, V-Path correction, Single or Echo-to-Echo, Encoded B-scan

Includes:

- Detector unit

- Charging cable

- mini USB cable

- User manual CD

- Getting started guide

- 2x sensor cable units part No. U8800185.

- accessory part M110-RM

- accessory part M112-RM.

- Blue plastic carry case.

- Users Manual

Also you can check product : Used Olympus Nortec 600D Eddy Current Flaw Detector - Sale !!

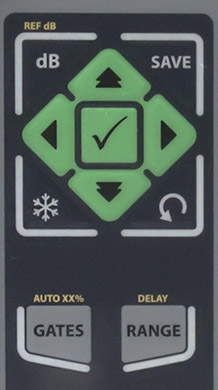

Olympus converges its latest advancements in high-performance digital circuitry and eddy current flaw detection into one compact and durable portable unit—the new NORTEC 600. With its crisp and vivid 5.7 inch VGA display and true full-screen mode, the NORTEC 600 is capable of producing highly visible and contrasting eddy current signals in any lighting condition.

The redesigned interface of the NORTEC 600 borrows the intuitive, knob-operated navigation of its NORTEC predecessors and combines it with the simple menu structure and highly efficient direct-access keys of other popular Olympus instruments. Available in four versatile models, the NORTEC 600 offers a wide range of innovative functionalities, including an Application Selection menu, an all-in-one display, real-time readings, and signal calibration in Freeze mode, ensuring that inspections are quick and easy for any level of operator.

Reliable and Robust

Based on an already field-proven instrument case, the NORTEC 600 is built for endurance in harsh field conditions. Its casing’s durability and resistance to extreme weather makes the NORTEC 600 an instrument you can trust for any eddy current inspection job.

Key Features

| Portable and LightweightThe NORTEC 600 weighs only 1.6 kg and is delivered with a factory-installed hand strap that provides direct thumb access to the key controls, offering genuine handheld versatility to operators.

|

Versatility and CompatibilityFour Models for All Your NeedsThe NORTEC® 600 is available in four versatile instrument models to meet the widest range of inspection needs. From the basic model upward, each unit unlocks more features. For maximum convenience, additional features can also be unlocked remotely. |  |

| Supported feature or mode | N600 (basic) | N600C (conductivity) | N600S (scanner) | N600D (dual freq.) |

| Signal calibration in Freeze mode | √ | √ | √ | √ |

| Real-time readings | √ | √ | √ | √ |

| Application Selection | √ | √ | √ | √ |

| All-in-one display | √ | √ | √ | √ |

| PowerLink probe support | √ | √ | √ | √ |

| Conductivity and coating thickness measurement | √* | √ | √ | |

| Rotary scanner | √ | √ | ||

| Dual frequency and mixing | √ | |||

| *One conductivity probe 9222340 [U8690027], standard 9522103 [U8880111] and calibration shims 0320806 [U8840160] included. | ||||

Two Probe Connectors

All models of the NORTEC 600 come with the standard LEMO 16-way universal connector, as well as a BNC connector for absolute probes. Simply select the connector in the instrument interface. When reading from the BNC connector, the instrument features automatic internal balancing for hassle-free operation.

The 16-way LEMO connector also supports the PowerLink NORTEC technology, which features automatic probe recognition and instrument presets for quicker setups.

Compatible with Current Procedures and Other Manufacturers

To simplify inspection, the NORTEC 600 includes all the legacy modes and layouts used in existing NORTEC-specified procedures, as well as those used by many other equipment manufacturers. Standard impedance plane view, sweep mode (strip chart), split screens, adjustable null point, crosshairs, improved filter response, reference signal display, and several other useful features are all part of the NORTEC 600 package.

Offering compatibility with many other probe and rotary scanner manufacturers, the NORTEC 600’s accessories include cables and adaptors such as a 12-way LEMO, an 11-way Fischer, and more. The proper adaptor or scanner cable make it possible to benefit from all the outstanding capabilities of the NORTEC 600, without investing heavily in probes and accessories.

One of the Most Brilliant Displays in the Industry

Vibrant VGA DisplayThe NORTEC® 600 has one of the most brilliant displays available on the portable eddy current flaw detector market. The unique brightness, resolution, and definition of its 5.7 inch VGA display makes it possible to interpret eddy current signals at a distance. The user-selectable color schemes ensure that the display is equally clear and easy-to-read whether you are using the NORTEC 600 indoors or outside.

|

|

Easy Integration of NORTEC 600

The NORTEC® 600 merges seamlessly into any integrated eddy current detection system. Its numerous software and hardware features ensure that the instrument is capable of performing consistent flaw detection in industrial environments. The NORTEC 600 specifications and functionalities were designed with the integrator in mind.

|

SPECS :

| Housing | Overall dimensions (width × height × depth) | 236 mm × 167 mm × 70 mm |

|---|---|---|

| Weight | 1.7 kg, including lithium-ion battery. | |

| Standards or directives | EN-15548, CE, WEEE, FCC (USA), IC (Canada), RoHS (China), RCM (Australia and New Zealand). | |

| Power requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 Hz to 60 Hz. | |

| Input and Outputs | One USB 2.0 peripheral port, one standard VGA analog output port, one 15-pin I/O port (male) with 6 analog outputs, 3 alarm outputs. | |

| Environmental conditions | Operating temperature | –10 °C to 50 °C |

| Storage temperature | 0°C to 50°C (with batteries) and -20°C to 70°C (without batteries). | |

| IP rating | Designed to meet requirements of IP66. | |

| Battery | Battery type | Single lithium-ion rechargeable battery or optional AA-size alkaline batteries (in 8-cell holder). |

| Battery life | Up to 10 hours for standard operation; 6 hours to 8 hours when operating rotary scanners. | |

| Display | Display size (W × H, diagonal) | 117.4 mm × 88.7 mm, 146.3 mm |

| Display type | Full VGA (640 × 480 pixels) color, transflective LCD (liquid crystal display). | |

| Screen modes | Normal or Full screen, 8 color schemes. | |

| Grids and display tools | Choice of 5 grids; crosshairs (single trace displays only). | |

| Connectivity and memory | PC software | NORTEC PC software, included in base NORTEC 600 kit. NORTEC PC allows viewing saved files and printing reports. |

| Data storage | 500 traces of 120 s max featuring user-selectable on-board preview. | |

| Interface | Languages | English, Spanish, French, German, Italian, Japanese, Chinese, Russian, Portuguese, Polish, Dutch, Czech, Hungarian, Swedish, and Norwegian. |

| Applications | Application Selection menu for easy and rapid configuration. Automatic lift-off key. | |

| Real-Time Readings | Choice of up to 2 real-time readings measuring signal characteristics (selection of 5 amplitude measurements and 1 angle measurement). | |

| Eddy Current Specifications (all NORTEC models) | Probe types | Absolute and differential in either bridge or reflection configuration. The instrument is fully compatible with NORTEC PowerLink probes, as well as other main probe and accessory suppliers. |

| Probe connectors | 16-pin LEMO and BNC featuring internal automatic balancing for BNC connector (absolute probes). | |

| Frequency range | 10 Hz to 12 MHz | |

| Gain | 0 dB to 100 dB in 0.1 or 1 dB increments. | |

| Rotation | 0° to 359.9° in 0.1° or 1° increments. | |

| Sweep | Variable from 0.005 s to 10 s per division (total of 13.3 divisions with FINE grid). | |

| Filters | Low-pass: 10 Hz to 2000 Hz and wide band. High-pass: off or 5 Hz to 1000 Hz, user-selectable in constant “figure 6” or “figure 8” filter type. Continuous null (low-frequency HP filter): 0.2 Hz, 0.5 Hz, 1.0 Hz. | |

| Probe drive | LOW, MEDIUM, and HIGH (2 V, 5 V, 8 V). | |

| Display erase, persistence | Display erase (0.1 s to 60 s), persistence (0.1 s to 10 s) | |

| Available alarm types | 3 simultaneous alarms. Choices include BOX (rectangle), POLAR (circle), SECTOR (pie), SWEEP (time-based), CONDUCTIVITY, and COATING THICKNESS. | |

| Conductivity (NORTEC 600C, NORTEC 600S, and NORTEC 600D) | Frequency | 60 kHz or 480 kHz |

| Digital conductivity specification | Digital conductivity display from 0.9% to 110% IACS or 0.5 to 64 MS/m. Accuracy within ±0.5% IACS from 0.9% to 65% IACS and within ±1.0% of values over 62%. Meets or exceeds BAC 5651 specifications. | |

| Non-conductive coating thickness | Can measure non-conductive coating thickness from 0 mm to 0.648 mm. Accuracy of 0.025 mm (±0.001 in.) over a 0 mm to 0.64 mm range. | |

| Scanners (NORTEC 600S and NORTEC 600D) | Scanner compatibility | Operates Olympus scanners (MiniMite, SpitFire, RA-2000, and PS-5) and other major supplier scanners, from 120 RPM to 3000 RPM. |

| Dual Frequency (NORTEC 600D) | Frequency adjustment (dual frequency mode) | Two fully independent frequencies, operating in simultaneous injection. |

| MIX options | F1 - F2, F1 F2, and automatic true mixing. |

If you work in explosive atmospheres, the NORTEC 600 Ex flaw detector conforms to the requirements of the ATEX directive. For more information, read our FAQ on the ATEX directive..

Standard Inclusions

The NORTEC® 600 is available in any of the following configurations:

Model: Basic, Conductivity (C), Scanner (S), and Dual Frequency (D).

Power cord: Over 11 power cord models available (for the DC charger).

Keypad and instruction label: English, international (icons), Chinese, or Japanese.

“Getting Started” print manual: over 9 languages available.

Items included in all NORTEC 600 models*: NORTEC 600 instrument with factory-installed hand strap, getting started manual, factory certificate, rigid transport case, DC charger with power cord, Li-Ion battery, AA battery tray, USB communication cable, MicroSD memory card and adaptor, and NORTEC PC software and product manuals disc.

*Standard inclusions may vary depending on your location. Contact your local distributor.

Additional items included in NORTEC 600C model only: 19 mm, 60 kHz conductivity probe, conductivity calibration standard (set of 2: 29% and 59%), and calibration shims.

Olympus converges its latest advancements in high-performance digital circuitry and eddy current flaw detection into one compact and durable portable unit—the new NORTEC® 600. With its crisp and vivid 5.7 inch VGA display and true full-screen mode, the NORTEC 600 is capable of producing highly visible and contrasting eddy current signals in any lighting condition.

The redesigned interface of the NORTEC 600 borrows the intuitive, knob-operated navigation of its NORTEC predecessors and combines it with the simple menu structure and highly efficient direct-access keys of other popular Olympus instruments. Available in four versatile models, the NORTEC 600 offers a wide range of innovative functionalities, including an Application Selection menu, an all-in-one display, real-time readings, and signal calibration in Freeze mode, ensuring that inspections are quick and easy for any level of operator.

Reliable and Robust

Based on an already field-proven instrument case, the NORTEC 600 is built for endurance in harsh field conditions. Its casing’s durability and resistance to extreme weather makes the NORTEC 600 an instrument you can trust for any eddy current inspection job.

Key Features

| Portable and LightweightThe NORTEC 600 weighs only 1.6 kg and is delivered with a factory-installed hand strap that provides direct thumb access to the key controls, offering genuine handheld versatility to operators.

|

Versatility and CompatibilityFour Models for All Your NeedsThe NORTEC® 600 is available in four versatile instrument models to meet the widest range of inspection needs. From the basic model upward, each unit unlocks more features. For maximum convenience, additional features can also be unlocked remotely. |  |

| Supported feature or mode | N600 (basic) | N600C (conductivity) | N600S (scanner) | N600D (dual freq.) |

| Signal calibration in Freeze mode | √ | √ | √ | √ |

| Real-time readings | √ | √ | √ | √ |

| Application Selection | √ | √ | √ | √ |

| All-in-one display | √ | √ | √ | √ |

| PowerLink probe support | √ | √ | √ | √ |

| Conductivity and coating thickness measurement | √* | √ | √ | |

| Rotary scanner | √ | √ | ||

| Dual frequency and mixing | √ | |||

| *One conductivity probe 9222340 [U8690027], standard 9522103 [U8880111] and calibration shims 0320806 [U8840160] included. | ||||

Two Probe Connectors

All models of the NORTEC 600 come with the standard LEMO 16-way universal connector, as well as a BNC connector for absolute probes. Simply select the connector in the instrument interface. When reading from the BNC connector, the instrument features automatic internal balancing for hassle-free operation.

The 16-way LEMO connector also supports the PowerLink NORTEC technology, which features automatic probe recognition and instrument presets for quicker setups.

Compatible with Current Procedures and Other Manufacturers

To simplify inspection, the NORTEC 600 includes all the legacy modes and layouts used in existing NORTEC-specified procedures, as well as those used by many other equipment manufacturers. Standard impedance plane view, sweep mode (strip chart), split screens, adjustable null point, crosshairs, improved filter response, reference signal display, and several other useful features are all part of the NORTEC 600 package.

Offering compatibility with many other probe and rotary scanner manufacturers, the NORTEC 600’s accessories include cables and adaptors such as a 12-way LEMO, an 11-way Fischer, and more. The proper adaptor or scanner cable make it possible to benefit from all the outstanding capabilities of the NORTEC 600, without investing heavily in probes and accessories.

One of the Most Brilliant Displays in the Industry

Vibrant VGA DisplayThe NORTEC® 600 has one of the most brilliant displays available on the portable eddy current flaw detector market. The unique brightness, resolution, and definition of its 5.7 inch VGA display makes it possible to interpret eddy current signals at a distance. The user-selectable color schemes ensure that the display is equally clear and easy-to-read whether you are using the NORTEC 600 indoors or outside.

|

|

Easy Integration of NORTEC 600

The NORTEC® 600 merges seamlessly into any integrated eddy current detection system. Its numerous software and hardware features ensure that the instrument is capable of performing consistent flaw detection in industrial environments. The NORTEC 600 specifications and functionalities were designed with the integrator in mind.

|

SPECS :

| Housing | Overall dimensions (width × height × depth) | 236 mm × 167 mm × 70 mm |

|---|---|---|

| Weight | 1.7 kg, including lithium-ion battery. | |

| Standards or directives | EN-15548, CE, WEEE, FCC (USA), IC (Canada), RoHS (China), RCM (Australia and New Zealand). | |

| Power requirements | AC Mains: 100 VAC to 120 VAC, 200 VAC to 240 VAC, 50 Hz to 60 Hz. | |

| Input and Outputs | One USB 2.0 peripheral port, one standard VGA analog output port, one 15-pin I/O port (male) with 6 analog outputs, 3 alarm outputs. | |

| Environmental conditions | Operating temperature | –10 °C to 50 °C |

| Storage temperature | 0°C to 50°C (with batteries) and -20°C to 70°C (without batteries). | |

| IP rating | Designed to meet requirements of IP66. | |

| Battery | Battery type | Single lithium-ion rechargeable battery or optional AA-size alkaline batteries (in 8-cell holder). |

| Battery life | Up to 10 hours for standard operation; 6 hours to 8 hours when operating rotary scanners. | |

| Display | Display size (W × H, diagonal) | 117.4 mm × 88.7 mm, 146.3 mm |

| Display type | Full VGA (640 × 480 pixels) color, transflective LCD (liquid crystal display). | |

| Screen modes | Normal or Full screen, 8 color schemes. | |

| Grids and display tools | Choice of 5 grids; crosshairs (single trace displays only). | |

| Connectivity and memory | PC software | NORTEC PC software, included in base NORTEC 600 kit. NORTEC PC allows viewing saved files and printing reports. |

| Data storage | 500 traces of 120 s max featuring user-selectable on-board preview. | |

| Interface | Languages | English, Spanish, French, German, Italian, Japanese, Chinese, Russian, Portuguese, Polish, Dutch, Czech, Hungarian, Swedish, and Norwegian. |

| Applications | Application Selection menu for easy and rapid configuration. Automatic lift-off key. | |

| Real-Time Readings | Choice of up to 2 real-time readings measuring signal characteristics (selection of 5 amplitude measurements and 1 angle measurement). | |

| Eddy Current Specifications (all NORTEC models) | Probe types | Absolute and differential in either bridge or reflection configuration. The instrument is fully compatible with NORTEC PowerLink probes, as well as other main probe and accessory suppliers. |

| Probe connectors | 16-pin LEMO and BNC featuring internal automatic balancing for BNC connector (absolute probes). | |

| Frequency range | 10 Hz to 12 MHz | |

| Gain | 0 dB to 100 dB in 0.1 or 1 dB increments. | |

| Rotation | 0° to 359.9° in 0.1° or 1° increments. | |

| Sweep | Variable from 0.005 s to 10 s per division (total of 13.3 divisions with FINE grid). | |

| Filters | Low-pass: 10 Hz to 2000 Hz and wide band. High-pass: off or 5 Hz to 1000 Hz, user-selectable in constant “figure 6” or “figure 8” filter type. Continuous null (low-frequency HP filter): 0.2 Hz, 0.5 Hz, 1.0 Hz. | |

| Probe drive | LOW, MEDIUM, and HIGH (2 V, 5 V, 8 V). | |

| Display erase, persistence | Display erase (0.1 s to 60 s), persistence (0.1 s to 10 s) | |

| Available alarm types | 3 simultaneous alarms. Choices include BOX (rectangle), POLAR (circle), SECTOR (pie), SWEEP (time-based), CONDUCTIVITY, and COATING THICKNESS. | |

| Conductivity (NORTEC 600C, NORTEC 600S, and NORTEC 600D) | Frequency | 60 kHz or 480 kHz |

| Digital conductivity specification | Digital conductivity display from 0.9% to 110% IACS or 0.5 to 64 MS/m. Accuracy within ±0.5% IACS from 0.9% to 65% IACS and within ±1.0% of values over 62%. Meets or exceeds BAC 5651 specifications. | |

| Non-conductive coating thickness | Can measure non-conductive coating thickness from 0 mm to 0.648 mm. Accuracy of 0.025 mm (±0.001 in.) over a 0 mm to 0.64 mm range. | |

| Scanners (NORTEC 600S and NORTEC 600D) | Scanner compatibility | Operates Olympus scanners (MiniMite, SpitFire, RA-2000, and PS-5) and other major supplier scanners, from 120 RPM to 3000 RPM. |

| Dual Frequency (NORTEC 600D) | Frequency adjustment (dual frequency mode) | Two fully independent frequencies, operating in simultaneous injection. |

| MIX options | F1 - F2, F1 F2, and automatic true mixing. |

If you work in explosive atmospheres, the NORTEC 600 Ex flaw detector conforms to the requirements of the ATEX directive. For more information, read our FAQ on the ATEX directive..

Standard Inclusions

The NORTEC® 600 is available in any of the following configurations:

Model: Basic, Conductivity (C), Scanner (S), and Dual Frequency (D).

Power cord: Over 11 power cord models available (for the DC charger).

Keypad and instruction label: English, international (icons), Chinese, or Japanese.

“Getting Started” print manual: over 9 languages available.

Items included in all NORTEC 600 models*: NORTEC 600 instrument with factory-installed hand strap, getting started manual, factory certificate, rigid transport case, DC charger with power cord, Li-Ion battery, AA battery tray, USB communication cable, MicroSD memory card and adaptor, and NORTEC PC software and product manuals disc.

*Standard inclusions may vary depending on your location. Contact your local distributor.

Additional items included in NORTEC 600C model only: 19 mm, 60 kHz conductivity probe, conductivity calibration standard (set of 2: 29% and 59%), and calibration shims.

The OmniScan MX

A Field-Proven, Dependable Instrument

With thousands of units being used throughout the world, the OmniScan® MX is a field-proven, reliable instrument that is built to withstand harsh and demanding inspection conditions. Compact and lightweight, its two Li-ion batteries provide up to 6 hours of manual or semi-automated inspection time.

The highly legible 8.4 in. (213 mm) real-time color display of the

MX enables you to see defects and details under any light conditions. Navigate your way through the instrument’s simple and intuitive interface using the scroll knob and function keys, or by connecting a USB mouse to facilitate the inspection analysis.

One Platform, Two Modules, Three Technologies: More Flexibility

To meet the requirements of a broader range of applications, eddy current testing (ECT), eddy current array (ECA) and the new bond testing (BT) C-scan technology are available in two module versions. Both of these modules are compatible with the MXE (ECT/ECA) and MXB (BT C-scan) software, providing easy transition between technologies and a very short learning curve.

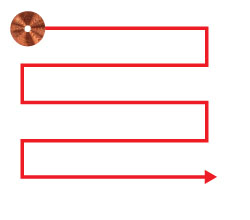

ECA is just like ECT

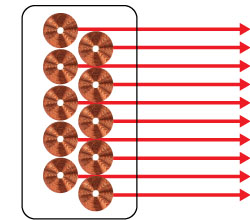

Large Coverage, Fast Scanning, and Higher Probability of Detection

Eddy current array (ECA) technology incorporates several traditional bridge or reflection (driver-pickup) probe coils in order to achieve a much larger coverage in a single inspection pass. Additionally, each ECA probe model is carefully designed to maintain a high probability of detection of a targeted defect range, all along the probe length. With the OmniScan® MX ECA, you can use ECA probes at fast manual-inspection speeds, offering a powerful and productive inspection with color representation and archiving capability.

Single coil: raster scanning |

Array probe: one-line scanning |

Inspection through Thin Coatings

Eddy current testing (ECT) technology works on the principle of magnetic coupling of a probe sensor (coil) close to a test specimen (conductive material, ferromagnetic or non-ferromagnetic), generating eddy currents inside the test specimen, and displaying signals on the instrument’s impedance plane. With eddy current technology, you can detect defects through thin coatings (such as paint), as long as the distance from the probe to the metal is kept reasonably low—typically in the order of 0.5 mm to 2.0 mm.

As eddy current array and ECT technology share the same basic principles (and physics), it can also perform inspections through paint while offering all advantages of ECA, including large coverage, fast scanning, high probability of detection and color imaging.

Specification :

| OmniScan MX | Overall dimensions (W x H x D) | 321 mm x 209 mm x 125 mm (12.6 in. x 8.2 in. x 5.0 in.) |

|---|---|---|

| Weight | 4.6 kg (10.1 lb), including module and one battery | |

| Display | 21 cm (8.4 in.) TFT LCD Display, 800 pixels x 600 pixels, 16 million colors | |

| Power supply | Smart Li-ion batteries (up to 2), and DC-in voltage 15 V to 18 V (min. 50 W) | |

| Battery Life | Minimum 6 hours with two batteries; minimum 3 hours per battery under normal operating conditions | |

| Data storage | CompactFlash card, most standard USB storage devices, or through fast Ethernet, internal 32-MB DiskOnChip | |

| I/O ports | 3 USB ports, Video output Video out (SVGA), Ethernet 10/100 Mbps, 2-axis encoders, 4 digital inputs (TTL). | |

| Operating temperature range | 0 °C to 40 °C; 0 °C to 35 ºC with 32:128 PA (32 ºF to 104 ºF; 32 ºF to 95 ºF with 32:128 PA) | |

| Storage temperature range | –20 °C to 70 °C (–4 ºF to 158 ºF) Relative humidity 0 % to 95 % noncondensing. No air intake; splashproof design. | |

| MX Module Compatibility | OMNI-M-ECT4 | Supports conventional eddy current and bond testing C-scan (adaptors not included) |

| OMNI-M-ECA4-32 | Supports eddy current arrays, conventional eddy current, and bond testing C-scan (adaptors not included) | |

| ECT/BT and ECA modules | Connectors | BNC Absolute Probe (ECT), 4-channel Universal Fischer 19 pins (ECT and BT), and OmniScan connector for ECA probes |

| Number of channels | 1 to 4 (ECT); 32 (ECA), expandable up to 64 with external multiplexer; 1 (BT) with adaptor | |

| Probe compatibility | Absolute, differential, bridge, reflection (driver-pickup) for both ECT and ECA probes. Support select BondMaster pitch-catch probes through use of an adaptor (scanner also required). | |

| Probe recognition | Automatic probe recognition and setup for ECA and BT probes. | |

| Frequencies | 2 typical for most ECA and ECT setups or up to 8 on custom ECT applications or Bond Testing C-scan | |

| Operating frequency | 20 Hz to 6 MHz | |

| Maximum voltage | 12 Vp-p into 10 Ω | |

| Gain | ECT and ECA: 34 dB to 74 dB. BT: 28 dB to 68 dB. Additional adjustable software gain of 0 dB to 30 dB. | |

| Phase rotation | 0° to 360° with increments of 0.1° | |

| Acquisition (measurement) rate | 1 Hz to 15 kHz, variable depending on configurations. | |

| A/D resolution | 16 bits | |

| Filtering | FIR low-pass, FIR high-pass, FIR band-pass, FIR band-stop (adjustable cutoff frequency), median filter (variable from 2 points to 200 points), mean filter (variable from 2 points to 200 points) | |

| Channel processing | True automatic mixing, sensitivity normalization and encoder calibration | |

| Encoders | Time-based, one line scan or raster scan (2 axis) | |

| Alarms | 3 alarms, each configurable as Pie, Box, Ring/Circle. Alarm output as Visual, TTL and Sound. | |

| Analog outputs | Yes - one channel only. |

Also you can check product : New Olympus EPOCH 6LT Portable Flaw Detector - Sale !!

The result of over 10 years of proven leadership in modular NDT test platforms, the OmniScan MX has been the most successful portable and modular phased array test instrument produced by Olympus to date, with thousands of units in use throughout the world.

Olympus now offers a new PA module with TOFD, a new UT module, as well as new software programs (NDT SetupBuilder and new OmniPC version) that expand the capabilities of the successful OmniScan MX2 platform and improve the workflow efficiency of nondestructive testing inspections.

Building on a Solid BasisThis second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. Designed for NDT experts, this high-end, scalable platform delivers true next-generation NDT performance. The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and automated inspection performance—all in a portable, modular instrument. |

Faster Is Better!Powerstart your day with the OmniScan MX2. The OmniScan MX2 simplifies and speeds up the setup process with its intuitive step-by-step Wizard, so you can start testing quickly. Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in. (26.4 cm) screen, new and unique intuitive touch-screen capabilities, and faster data transfer, the MX2 enables you to get to your next inspection quicker. |  |

More than an Instrument-A Solution Provider

The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Olympus offers a complete product range that includes phased array probes, scanners, analysis software, and accessories, all of which are integrated and packaged into rapidly deployable, application-specific solutions for a quick return on your investment. In addition, Olympus offers a high-quality global calibration and repair service, backed by a team of phased array application experts to ensure that you get the support you need.

Pressure Vessel Weld Inspection |  Composite Inspection |  Weld Inspection of Small-Diameter Pipes |  Manual and Semiautomated |

Modular Instrument

A Platform that Evolves as your Needs Grow

Designed to secure both your current and future phased array investments, the OmniScan MX2 houses more than 10 different Olympus modules. You can be confident that you will get the most out of your investment as specifications will continue to evolve with your needs through constant software updates.

State of the Art PA2 and UT2 Modules

As a world leader in phased array technology, Olympus has released a new line of modules compatible with MX2 instrument.

PA2The new phased array offer-led by the new innovative PA2 modules, features multiple improvements, such as: Best Phased Array and TOFD Signal Quality Ever

More Multi-group Capabilities

General Hardware Improvements

|  16:64 PA2 16:128 PA2 32:128 PA2 32:128PR PA2 |

UT2The new conventional ultrasound module features the same UT-channel technology as the PA2 modules, but offers twice as many channels. |  2 ch. UT2 |

OmniScan MX2 Mainframe Specifications

| General | Overall dimensions (W x H x D) | 325 mm x 235 mm x 130 mm (12.8 in. x 9.3 in. x 5.1 in.) |

|---|---|---|

| Weight | 3.2 kg (7 lb), no module and one battery | |

| Data Storage | Storage devices | SDHC card*, most standard USB storage devices, or fast Ethernet. *Lexar® brand memory cards are recommended for optimized results. |

| Data file size | 300 MB | |

| I/O Ports | USB ports | 3 |

| Audio alarm | Yes | |

| Video output | Video out (SVGA) | |

| Ethernet | 10/100 Mbps | |

| I/O Lines | Encoder | 2-axis encoder line (quadrature, up, down, or clock/direction) |

| Digital input | 4 digital TTL inputs, 5 V | |

| Digital output | 4 digital TTL outputs, 5 V, 15 mA | |

| Acquisition on/off switch | Remote acquisition enabled TTL, 5 V | |

| Power output line | 5 V, 500 mA power output line (short-circuit protected) | |

| Alarms | 3 TTL, 5 V, 15 mA | |

| Analog output | 2 analog outputs (12 bits) ±5 V in 10 kΩ | |

| Pace input | 5 V TTL pace input | |

| Display | Display size | 26.4 cm (10.4 in.) (diagonal) |

| Resolution | 800 pixels x 600 pixels | |

| Brightness | 700 cd/m2 | |

| Number of colors | 16 million | |

| Type | TFT LCD | |

| Power Supply | Battery type | Smart Li-ion battery |

| Number of batteries | 1 or 2 (battery chamber accommodates two hot-swappable batteries) | |

| Battery life | Minimum 7 hours with two batteries | |

| Environmental Specifications | Operating temperature range | -10 °C to 45 °C (14 ºF to 113 ºF) |

| Storage temperature range | -20 °C to 60 °C (-4 ºF to 140 ºF) with batteries -20 °C to 70 °C (-4 ºF to 158 ºF) without batteries | |

| Relative humidity | Max. 70% RH at 45°C noncondensing | |

| Ingress Protection Rating | Designed for IP66 | |

| Shockproof rating | Drop-tested according to MIL-STD-810G 516.6 | |

| MX2 Module Compatibility | MXU 4.1R8 and later | OMNI-M2-PA32128PR |

| MXU 4.0 and later | OMNI-M2-PA1664 | |

| OMNI-M2-PA16128 | ||

| OMNI-M2-PA32128 | ||

| OMNI-M2-UT-2CH | ||

| MXU 3.1 and MXU 4.1R12 and later | OMNI-M-UT-8CH |

Phased Array Module Specifications (Applies to OMNI-M2 modules)

| General | Overall dimensions (W x H x D) | 226 mm x 183 mm x 40 mm (8.9 in. x 7.2 in. x 1.6 in.) |

|---|---|---|

| Weight | 1.6 kg (3.5 lb) | |

| Connectors | 1 Phased Array connector: Olympus PA connector 2 UT connectors: LEMO 00 | |

| Number of focal laws | 256 | |

| Probe recognition | Automatic probe recognition | |

| Pulser/Receiver | Aperture | 32 elements* |

| Number of elements | 128 elements* |

| Pulser | PA Channels | UT Channels |

| Voltage | 40 V, 80 V, and 115 V | 95 V, 175 V, and 340 V |

| Pulse width | Adjustable from 30 ns to 500 ns, resolution of 2.5 ns | Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns |

| Pulse shape | Negative square pulse | Negative square pulse |

| Output impedance (32:128PR model) | 35 Ω in pulse-echo mode 30 Ω in pitch-catch mode | < 30 Ω |

| Output impedance (all other models) | 25 Ω | < 30 Ω |

| Receiver | PA Channels | UT Channels |

| Gain | 0 dB to 80 dB, maximum input signal 550 mVp-p (full-screen height) | 0 dB to 120 dB maximum input signal 34.5 Vp-p (full-screen height) |

| Input impedance (32:128PR model) | 50 Ω in pulse-echo mode 90 Ω in pitch-catch mode | 60 Ω in pulse-echo mode 50 Ω in pitch-catch mode |

| Input impedance (all other models) | 65 Ω | 60 Ω in pulse-echo mode 50 Ω in pitch-catch mode |

| System bandwidth | 0.5 MHz to 18 MHz (NOTE: The previously stated 0.6 MHz lower limit used a strict −3 dB attenuation for the cutoff frequency.) | 0.25 MHz to 28 MHz (-3 dB) |

| Beamforming | Scan type | Sectorial and linear |

|---|---|---|

| Group quantity | Up to 8 | |

| Data Acquisition | Effective digitizing frequency | Up to 100 MHz |

| Maximum pulsing rate | Up to 10 kHz (C-scan) |

| Data Processing | PA Channels | UT Channels |

| Number of data points | Up to 8,192 | |

| Real-time averaging | 2, 4, 8, 16 | 2, 4, 8, 16, 32, 64 |

| Rectifier | RF, full wave, half wave , half wave – | |

| Filtering | 3 low-pass, 3 band-pass, and 5 high-pass filters. | 3 low-pass, 6 band-pass, and 3 high-pass filters (8 low-pass filters when configured in TOFD) |

| Video filtering | Smoothing (adjusted to probe frequency range) | |

| Data Visualization | A-scan refresh rate | Real time: 60 Hz |

|---|---|---|

| Data Synchronization | On internal clock | 1 Hz to 10 kHz |

| On encoder | On 2 axes: from 1 to 65,536 steps | |

| Programmable Time-Corrected Gain (TCG) | Number of points | 32: One TCG curve per focal law |

| Alarms | Number of alarms | 3 |

| Conditions | Any logical combination of gates | |

| Analog outputs | 2 |

Olympus Vanta L handheld X-ray fluorescence (XRF) analyzer designed for customers who demand the ruggedness, power, speed and ease of use that Vanta analyzers provide in a cost-effective Si-PIN X-ray detector in a cost-effective model.

The Vanta L Series delivers a fast return on investment in applications including positive material identification (PMI), quality assurance (QA), metal fabrication, scrap metal and car catalyst recycling, precious metal analysis and environmental inspections.

Olympus Vanta L XRF Analyzer sale includes;

- Vanta L with Alloy & Metals Mode

- Case

- Accessories

- Manual

- Charger

- Cable

- Stand

Vanta L Series analyzers deliver all of the features and benefits that have made Vanta analyzers so popular. L Series analyzers can be calibrated for alloy, precious metal and geochem applications and are built for maximum uptime and reliability. Rugged features include:

- IP65 rated for protection against dust and water

- Drop tested (MIL-STD 810 G)

- Built to withstand a temperature range of -10 °C to 50 °C (14 °F to 122 °F)*

In addition to being so rugged, L Series analyzers offer advanced technology and connectivity features. The analyzers incorporate Olympus Axon technology, a breakthrough in XRF signal processing for stable results in any environment, and user-friendly features including:

- Optional Wi-Fi and cloud connectivity for fast decision making and easily accessible results

- Fleet management tools and a customizable user interface to help minimize operator training

- Intuitive interface and responsive touch screen, enabling users to spend more time interpreting results than operating the analyzer

Olympus Vanta L Series analyzers deliver the durability, power and ease of use Vanta analyzers are known for, in a cost-effective model.

| Vanta Specifications | |

| Dimensions (W × H × D) | 8.3 cm × 28.9 cm × 24.2 cm (3.25 in. × 11.4 in. × 9.5 in.) |

| Weight | M series, C series, and L series: 1.70 kg (3.75 lb) with battery, 1.48 kg (3.24 lb) without battery Element: 1.54 kg (3.39 lb) with battery, 1.32 kg (2.91 lb) without battery |

| Excitation Source | 4-watt X-ray tube with application-optimized anode material (rhodium (Rh), silver (Ag), or tungsten (W)) M series (Rh & W) and C series (Ag): 8–50 kV C series (Rh & W): 8–40 kV L series (W) and Element (W): 35 kV (2 watts) |

| Primary Beam Filtration | M and C series: 8-position autoselected filter per beam per mode; optional collimation to 3 mm diameter beam spot L series and Element: Fixed aluminum filter and no internal collimation |

| Detector | M series: Large-area silicon drift detector C series: Silicon drift detector L series and Element: Silicon PIN detector |

| Power | Removable 14.4 V Li-ion battery with hot-swap capability (M, C, and L series only) or 18 V power transformer 100–240 VAC, 50–60 Hz, 70 W max |

| Display | 800 × 480 (WVGA) LCD with capacitive touch screen supporting gesture control |

| Operating Environmental | emperature range for the M, C, and L series: −10 °C to 50 °C (14 °F to 122 °F), (continuous duty cycle with optional fan); Temperature range for the Element: −10 °C to 45 °C (14 °F to 113 °F) Humidity: 10% to 90% relative humidity non-condesing |

| Drop Test | Military Standard 810-G 4-foot (1.3 M) drop test |

| IP Rating and Detector Shutter | M series, and Element IP54: dust protected and protected against water splashing from all directions C and L series IP55: dust protected and protected against water jets from all directions M and C series: Solid detector shutter to help prevent detector damage |

| Pressure Correction | M and C series: Built-in barometer for automatic altitude and air density correction |

| GPS | M, C, and L series: Embedded GPS / GLONASS receiver |

| Operating System | Linux Cloud enabled with user fleet manager capability |

| Data Storage | microSD™ slot with removable 1 GB industrial SD card included |

| USB | (2) USB 2.0 type A host ports for accessories such as wireless LAN, Bluetooth®, and USB flash drives. (1) USB 2.0 type mini-B port for connection to computer |

| Wireless LAN | Supports 802.11 b/g/n (2.4 GHz) cable optional USB adaptor |

| Bluetooth | Supports Bluetooth with an optional USB adaptor |

| Aiming Camera | Full VGA CMOS camera (Optional on M, C, and L series) |

| Panoramic Camera | 5-megapixel CMOS camera with autofocus lens (Optional on M, C, and L series) |

| Warranty | M, C, and L series: Three-year warranty; Element: One-year warrant |

| Selected Optional Accessories | M, C, and L series: Field Stand, Soil Foot, Holster, Work Station, Weld Mask, Hot Heel, Probe Shield, and VLW Collimation Mask (L series only) Element: Field Stand, Soil Foot, and Holster |

Housed in the field-proven rugged and portable OmniScan X3 enclosure, the OmniScan X3 64 flaw detector’s powerful focusing capabilities supported by its larger element-aperture capacity enable you to fully exploit 64-element phased array probes and 128-element aperture TFM. Utilize its enhanced performance to meet the inspection challenges of thick and attenuative materials and expand your potential to develop new procedures for a wider range of applications.

The OmniScan X3 flaw detector is a complete phased array toolbox. Powerful tools, including total focusing method (TFM) imaging and advanced visualization capabilities, backed by its high image quality enable you to complete your inspection with greater confidence.

Benefit from 64-Pulser Phased Array

Exploit the full potential of 64-element phased array probes using the OmniScan X3 64 flaw detector to achieve improved resolution at the focal point.

Slide Right: Acquired using a 32-channel OmniScan X3 unit with a 64-element probe (5L64-A32 model), this S-scan is a high-quality image but the resolution reflects the fact that only the middle 32 elements could be used for the focal law.

Slide Left: Using a full 64-element aperture (5L64-A32 probe), the OmniScan X3 64 flaw detector provides better PA resolution at the focal point, enabling you to more easily distinguish indications that are close together or in a cluster.

Access Full 128-Element Aperture TFM

Made possible by new generation electronics, TFM imaging offers better focusing capabilities for smaller indications and an improved signal-to-noise ratio (SNR). With its 128-element aperture capacity, the OmniScan X3 64 model provides enhanced image clarity.

Slide Right: This TFM image was acquired with 64 elements of a 128-element probe (3.5L128-I4 model) using an OmniScan X3 32-channel model.

Slide Left: Here, the OmniScan X3 64 flaw detector enabled us to use the full 128-element aperture of our 3.5 MHz, 128-element I4 probe. Note the improved resolution and reduced background noise.

Improved Phased Array

Up to 3x as fast as the OmniScan MX2 flaw detector (max pulse repetition frequency)

Single TOFD menu for an accelerated calibration workflow

800% high amplitude range reduces the need to rescan

Onboard Dual Linear Array and Dual Matrix Array probe support accelerates setup creation.

Ease Corrosion Monitoring Using Phased Array

Using phased array to inspect corrosion offers many benefits, including excellent coverage and resolution. However, becoming proficient in phased array techniques can be challenging. The OmniScan X3 flaw detector combines advanced functions such as gate synchronization with thoughtfully designed software and simplified menus, so you can obtain accurate data more easily. Configure your setup quickly thanks to its A-scan synchronization processing and manual time-corrected gain (TCG).

Acoustic Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TFM/FMC

Operating Environment

|

Vanta iX In-Line XRF Analyzer for Automated Material Analysis

The Olympus Vanta™ iX in-line X-ray fluorescence (XRF) analyzer gives you confidence in your products by automating material analysis and alloy identification on the manufacturing line:

- Delivers instant results for real-time process monitoring and 100% inspection

- Built to operate 24/7

- Configured to deliver pass/fail results, accurate grade ID, and material chemistry

100% Inspection for Metal Fabrication of Tubes, Bars, and Rods

For organizations adopting Industry 4.0 practices and 24/7 process control to verify alloys with pass/fail analysis, the Vanta iX analyzer delivers material verification and lot/heat control for bar, billet, tube, and rod manufacturing, as well as machined parts and customized components. Automating your testing with a Vanta iX analyzer adds a competitive edge to your finished product since you can demonstrate that materials are 100% tested and verified.

Scanning and Monitoring for Ore Grade Control in Mining

For geological processing and mining, the Vanta iX analyzer enables core scanning and on-belt analysis with real-time results to monitor process variability and ensure ore grade consistency. During on-belt analysis, the analyzer provides blending verification and process validation of concentrates.

Fast and Accurate Elemental Analysis for Continuous Quality Control

Like all Vanta electronics, the Vanta iX analyzer works fast while delivering reliable, actionable results to guide critical decisions.

- High resolution: ID a range of alloy grades—including light and heavy elements

- Fast, accurate results: the analyzer’s electronics provide high throughput, stability, and count rate

- Efficient: features a silicon drift detector (SDD) and the proven Axon Technology™ found in every Vanta analyzer

Easily Integrates into a Variety of Production Systems

The Vanta iX analyzer is versatile, compact, and easy to install—use the mounting holes on each side to mount the analyzer onto robotics and other systems. There is no external control box, so you can easily control the analyzer with either the Vanta Connect API or a PLC and discrete wire.

Connector options:

- Ethernet (RJ-45), enabling Power over Ethernet

- USB

- Discrete I/O (16 pins)

- AUX DC power

Rugged for Greater Uptime in Manufacturing Environments

The Vanta iX analyzer is built to endure the high levels of vibration, electromagnetic and acoustical noise, dust, and moisture of production facilities for increased reliability and uptime.

- Vibration tested (MIL-STD)

- IP54 rated

- Designed to operate from –10 °C to 50 °C (14 °F to 122 °F) with continuous testing

A built-in heat sink lowers the internal temperature, while fan attachment points are available if additional cooling is needed. The analyzer offers toolless window changes for fast maintenance.

Vanta iX Specifications

| Dimensions (W × H × D) | 10 cm × 7.9 cm × 26.6 cm (3.9 in. × 3.1 in. × 10.5 in.) |

| Weight | 2.4 kg (5.29 lb) |

| Excitation Source | X-ray tube: Rh or W anode (application optimized) 5–200 μA MR model: 8–50 keV (4 W max) CW model: 8–40 keV (4 W max) |

| Primary Beam Filtration | Eight filter positions automatically selected per beam per method |

| Detector | MR model: Large-area silicon drift detector CW model: Standard silicon drift detector |

| Power | Power over Ethernet (PoE) or 18 V AC power adaptor |

| Elemental Range | Method dependent: MR model: Mg–U CW model: Ti–U (with standard window and calibration) |

| Pressure Correction | Built-in barometer for automatic altitude and air pressure correction |

| IP Rating | IP54 |

| Operating Environment | Temperature range: –10 °C to 50 °C (14 °F to 122 °F) under continuous duty cycle Humidity: 10% to 90% relative humidity, non-condensing |

| Operating System | Linux |

| Application Software | Olympus proprietary data acquisition and processing package |

The EPOCH 600 Digital Ultrasonic Flaw Detector combines Olympus' industry leading conventional flaw detection capabilities with the efficiency of a highly portable, intuitive instrument. The EPOCH 600 flaw detector's blend of efficient menus and direct access keys allows you to take advantage of the highest quality flaw detection platform with exceptional ease of use.

The large, full VGA transflective display combined with our patent-pending digital high dynamic range receiver provides a stable, striking A-scan representation in any lighting condition. Available in two hardware configurations, the EPOCH 600 offers you the choice to adjust parameters with a knob or with a navigation area on the keypad. The EPOCH 600 is designed to meet the requirements of EN12668-1 and allows a full range of standard and optional flaw detection features. The rugged, ergonomic design allows use in nearly any inspection environment, while the flexible PerfectSquare™ pulser and digital filtering capabilities can tackle nearly any application.

Key Features

Designed to meet the requirements of EN12668-1

PerfectSquare™ tunable square wave pulser

Digital high dynamic range receiver

Eight digital filters for enhanced signal-to-noise ratio

2 kHz PRF for rapid scanning

Knob or navigation pad adjustment configurations

Large, full VGA sunlight readable display

Long battery life, supporting lithium-ion or alkaline batteries

Standard dynamic DAC/TVG and onboard DGS/AVG

2 GB MicroSD memory card for data transfers and storage

USB On-The-Go (OTG) for PC communication

Alarm and VGA outputs

Optional analog output

Economy with Quality

The EPOCH 600 combines the efficiency of a basic flaw detector with the quality of Olympus' most powerful fully digital ultrasonic instruments. A full range of dynamic, reliable inspection features are packaged with economy of size and ease of use. This optimal balance brings powerful flaw detection features within reach of any level of inspector.

Simple and Durable Operation

The EPOCH 600 design is focused on providing a very high level of flaw detection with the simplicity of a basic instrument. The EPOCH 600 is designed to be ergonomic, intuitive, and practical for both experienced and novice ultrasonic inspectors.

Intuitive User Interface

The EPOCH 600 user interface is based on the industry approved EPOCH 1000 Series imaging flaw detector. The EPOCH 600 combines a simple menu structure for instrument settings, calibration and software feature adjustment, with the EPOCH brand's hallmark direct-access key approach for critical inspection functions such as gain and gate adjustment, screen freeze, and file save. Supported in multiple languages, the EPOCH 600 user interface is intuitive for any level of operator.

Portable Design for All Inspection Environments

The EPOCH 600 is designed for use in nearly any inspection environment, from bench top testing in a laboratory to extreme outdoor and hazardous conditions. Designed for IP rating in either knob (IP66) or navigation pad (IP67) configurations, and tested to very high environmental and reliability standards, the EPOCH 600 allows users in any inspection environment to feel confident in both the performance and durability of the instrument. The instrument is tested for vibration, shock, explosive atmosphere, and wide temperature ranges. And with a battery life to exceed 12 hours, the EPOCH 600 is the perfect solution for remote inspection locations.

Vibrant Full VGA Display

The EPOCH 600 features a full VGA (640 x 480 pixels) resolution display. The horizontal design of the EPOCH 600 optimizes the A-scan size and readability on this high quality display. Built with transflective technology, this VGA display provides excellent clarity in indoor, low lighting conditions using its powerful backlight, as well as in direct sunlight by using the ambient light as a pseudo-backlight.

Optimized Access to Powerful Features

The EPOCH 600 provides excellent quality ultrasonic performance. Based on the same digital architecture as the EPOCH XT, LTC and EPOCH 1000 Series, the EPOCH 600 provides flexible, powerful pulsing and receiving features to accommodate the needs of most flaw detection inspections.

Pulser/Receiver

The EPOCH 600 comes standards with powerful flaw detection capabilities, such as:

PerfectSquare tunable square wave pulser

Digital high dynamic range receiver

Eight 100% digital filter sets

Auto or manually adjustable PRF from 10 Hz to 2000 Hz

Pulser voltage from 100 V to 400 V

Amplitude resolution to /- 0.25%

Five customizable digital measurements

Options for Comfortable Navigation

In order to accommodate different user needs and preferences, the EPOCH 600 is available in two hardware configurations: one with an adjustment knob and the other with a navigation area on the keypad. The adjustment knob and the arrow keys on the navigation pad are responsible for parameter adjustment and value slewing.

Knob

The adjustment knob on the EPOCH 600 is used along with the CHECK and ESC keys to adjust parameter values in either coarse or fine increments. You have the ability to lock the knob to prevent accidental parameter value changes during an inspection. This configuration provides smooth value slewing for customers who prefer adjusting parameters using a knob. The knob configuration is designed to meet the requirements of IP66.

Navigation Pad

The EPOCH 600 navigation pad is a hallmark feature of the EPOCH flaw detectors. The up and down arrows on the navigation pad are used for coarse parameter adjustment, and the left and right arrows for fine adjustment. The navigation pad also contains additional functions and frequently used parameters such as gain, save, and the CHECK and ESC keys. The navigation pad configuration is designed to meet the requirements of IP67.

Portable, Rugged, and Ergonomic

Physical Features

The EPOCH 600 is a lightweight, portable flaw detector built to be rugged and flexible for nearly any inspection. Some key physical features include:

Large, full VGA resolution transflective display for vivid clarity in any indoor lighting and direct sunlight conditions

Rubber overmolded bumpers on all four corners for shock absorption and anti-marring considerations

Four-point harness connection for chest straps

"No tools" access to battery compartment and side I/O door

Continuous position stand with right angle crook for improved stability from 0 to 180 degrees

Gasketed side door for USB OTG connection and removable memory

Standard internal, rechargeable lithium-ion battery

Standard AA battery tray for extended portable use

Lightweight, ergonomic design for increased portability and ease of use

Instrument Inputs/Outputs

USB ports USB On-The-Go (OTG)

RS-232 port Yes

Video output VGA output standard

Analog output 1 analog output (optional), Selectable 1 V/10 V Full Scale, 4 mA max

Digital output 3 alarm outputs, 5V TTL, 10 mA

Environmental Ratings

IP rating IP rating Designed to meet the standards of the Ingress Protection (IP) rating number IP67 (navigation pad version) or IP66 (knob version) per IEC 60529-2004 (Degrees of Protection provided by enclosures - IP Code).

The product design was confirmed to meet the IP rating by means of Olympus NDT's internal design verification test process that occurs prior to the release of the product to production.

Explosive atmosphere Safe operation as defined by Class I, Division 2, Group D, as defined in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810F, Method 511.4, Procedure I.

Shock tested MIL-STD-810F, Method 516.5 Procedure I, 6 cycles each axis, 15 g, 11 ms half sine.

Vibration tested MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis

Operating temperature -10 °C to 50 °C (14 °F to 122 °F)

Battery storage temperature 0 °C to 50 °C (32 °F to 122 °F)

Specifications:

General

Overall dimensions (W x H x D) 236 mm x 167 mm x 70 mm (9.3 in. x 6.57 in. x 2.76 in.)

Weight 1.68 kg (3.72 lb), including lithium-ion battery

Languages English, Spanish, French, German, Japanese, Chinese, Portuguese

Transducer BNC or Number 1 LEMO

Data storage 50,000 IDs onboard, removable 2 GB MicroSD card (standard)

Battery type/life Single lithium-ion rechargeable standard/12 h to 13 h (lithium-ion), 3 h (alkaline)

Power requirements AC Mains: 100 VAC to120 VAC, 200 VAC to240 VAC, 50 Hz to 60 Hz

Display type Full VGA (640 x 480 pixels) transflective color LCD, 60 Hz update rate

Display dimensions (W x H, Diag.) 117 mm x 89 mm, 146 mm (4.62 in. x 3.49 in., 5.76 in.)

Pulser

Pulser Tunable Square Wave

PRF 10 Hz to 2000 Hz in 10 Hz increments

Energy settings 100 V, 200 V, 300 V or 400 V

Pulse width Adjustable from 25 ns to 5,000 ns (0.1 MHz) with PerfectSquare™ technology

Damping 50, 100, 200, 400 Ω

Gates

Measurement gates 2 fully independent gates for amplitude and TOF measurements

Gate start Variable over entire displayed range

Gate width Variable from 2 to 95% full screen height

Alarms Positive and Negative Threshold, Minimum Depth (Gate 1 and Gate 2)

Receiver

Gain 0 to 110 dB

Maximum input signal 20 V p-p

Receiver input impedance 400 Ω ± 5%

Receiver bandwidth 0.2 MHz to 26.5 MHz at –3 dB

Digital filter settings Eight digital filter sets standard (0.2-10 MHz, 2.0- 21.5 MHz, 8.0-26.5 MHz, Battery type/life Single lithium-ion rechargeable standard/12 h to 13 h (lithium-ion), 3 h (alkaline) 0.5-4 MHz, 0.2-1.2 MHz, 1.5-8.5 MHz, 5-15 MHz, DC-10 MHz

Rectification Full-wave, Positive Half-wave, Negative Halfwave, RF

System linearity Horizontal : ± 0.2% FSW

Vertical linearity 0.25% FSH, amplifier accuracy ± 1dB

Reject 0 to 80% FSH with Visual Warning

Amplitude measurement 0 to 110% full screen height with 0.25% resolution

Measurement rate Equivalent to PRF in all modes

Measurements

Measurement display locations 5 locations available (manual or auto selection)

Gate 1 Thickness, Soundpath, Projection, Depth, Amplitude, Time-Of-Flight, Gates Min./Max. Depth, Min./Max. Amplitude

Gate 2 Same as Gate 1

Echo-to-Echo Same as Gate 2-Gate 1

Other measurements Overshoot (dB) value for DGS/AVG, ERS (equivalent reflector size) for DGS/AVG, AWS D1.1,D1.5 rating (D), Reject Value

DAC.TVG Standard

DAC points Up to 50 points, 110 dB dynamic range

Special DAC modes Custom DAC (up to 6 curves)

Curved surface connection Standard OD or Bar correction for Angle Beam measurements

Standard Package

EPOCH 600 Digital ultrasonic flaw detector, AC or battery operation

Charger/AC adapter (100 VAC, 115 VAC, 230 VAC , 50 Hz or 60 Hz)

Rechargeable lithium-ion battery

AA battery tray

Transport case

Basic operation user's manual

Quick reference card

Comprehensive operation manual (CD)

The Vanta Element XRF analyzer series provides elemental analysis for fast alloy grade identification and sorting at an affordable price. The series is available in two cost-effective models:

- Vanta Element analyzer for affordable alloy ID

- Vanta Element-S analyzer for affordable alloy ID, including light element detection for magnesium (Mg), aluminum (Al), silicon (Si), sulfur (S), and phosphorus (P)

Both models feature fast grade ID and clear on-screen grade comparison to speed up metal testing for scrap sorting, metal manufacturing, and precious metals analysis.

The smartphone-like user interface is easy to use and easy to learn, helping to streamline both user training and the sorting process.

Vanta Specifications

| Vanta Element Model | Vanta Element-S Model | |

|---|---|---|

| Dimensions (W x H x D) | 8.3 x 28.9 x 24.2 cm (3.25 x 11.4 x 9.5 in.) | |

| Weight | 1.54 kg (3.39 lb) with battery, 1.32 kg (2.91 lb) without battery | |

| Excitation Source | 2-watt X-ray tube with 35 kV tungsten anode | 4-watt X-ray tube with 50kV silver (Ag) anode |

| Primary Beam Filtration | Fixed aluminum filter | 8-position filter wheel |

| Detector | Silicon PIN detector | Silicon drift detector (SDD) |

| Barometer | No | Yes |

| Power | Removable 14.4 V Li-Ion battery or 18 V power transformer 100–240 VAC, 50–60 Hz, 70 W max | |

| Display | 800 × 480 (WVGA) LCD with capacitive touch screen supporting gesture control | |

| Operating Environment | Temperature: −10 °C to 45 °C (14 °F to 113 °F) at 100% duty cycle Humidity: 10% to 90% relative humidity noncondensing | |

| Drop Test | Military Standard 810-G 4-foot (1.3 M) drop test | |

| IP Rating and Detector Shutter | IP54: dust protected and protected against water splashing from all directions | |

| Operating System | Linux® | |

| Data Storage | microSD™ slot with removable 1 GB Industrial SD card included | |

| USB | Two USB 2.0 type A host ports for accessories such as wireless LAN, Bluetooth®, and USB flash drives. One USB 2.0 type mini-B port for connection to computer. | |

| Wireless LAN | Supports 802.11 b/g/n (2.4 GHz) via optional USB adaptor | |

| Bluetooth | Supports Bluetooth® with an optional USB adaptor | |

| Warranty | One-year warranty | |

| Optional Accessories | Field Stand, Soil Foot, and Holster | |

Olympus Vanta L XRF Analyzer

Performs in All Environments

Fully functional in temperatures ranging from -14 °F to 122 °F* (-25.5 °C to 50 °C).

IP55 (C and L series) and IP54 (M series and Vanta Element) rated for protection against dust and water intrusion.

Analyze hot samples up to 950 °F (510 °C) using the optional hot heel faceplate.

Durable

All Vanta™ models are built to pass a 4-foot drop test (MIL-STD-810G) to help withstand typical forces in field and manufacturing environments.

Detector Protection

Automatic eyelid shutter helps prevent costly detector damage (C and M series models).

L series analyzers are equipped with a thick Kapton® window and feature tool-less window change.

Olympus Scientific Cloud™

Enables real-time data backups, downloads, and screen sharing.

Instantly update software and firmware.

Fleet management capabilities help you and your team view and access instrument health statistics and GPS location.

Simple Interface

Intuitive user interface simplifies alloy identification.

Smartphone-like gesture operation: swipe, flick, and tap.

Customize the home screen buttons for frequently used operations.

Easy Data Management

Instantly export analysis results through optional wireless connectivity, the Olympus Scientific Cloud, or a USB flash drive.

Customize data labels and exports with Vanta™ PC software.

The Vanta™ Series

Olympus manufactures Vanta™ X-ray fluorescence (XRF) analyzers to suit a variety of applications depending on your needs. Each Vanta analyzer is engineered for durability and analytical superiority.

L Series

Get the ruggedness, ease of use, and data management features of Vanta analyzers in a cost-effective PIN instrument. The L Series is designed for maximum uptime and a lower cost of ownership for reliability in the field.

Vanta Specifications

| Dimensions (W × H × D) | 8.3 cm × 28.9 cm × 24.2 cm (3.25 in. × 11.4 in. × 9.5 in.) |

| Weight | L series: 1.70 kg (3.75 lb) with battery, 1.48 kg (3.24 lb) without battery |

| Excitation Source | (W) and Element (W): 35 kV (2 watts) |

| Primary Beam Filtration | L series and Element: Fixed aluminum filter and no internal collimation |

| Detector | L series and Element: Silicon PIN detector |

| Power | Removable 14.4 V Li-ion battery with hot-swap capability (M, C, and L series only) or 18 V power transformer 100–240 VAC, 50–60 Hz, 70 W max |

| Display | 800 × 480 (WVGA) LCD with capacitive touch screen supporting gesture control |

| Operating evnerionment | Temperature range for the M, C, and L series: −10 °C to 50 °C (14 °F to 122 °F), (continuous duty cycle with optional fan); Temperature range for the Element: −10 °C to 45 °C (14 °F to 113 °F) Humidity: 10% to 90% relative humidity non-condensing |

| Drop Test | Military Standard 810-G 4-foot (1.3 M) drop test |

| IP rating and Detector Shutter | IP55: dust protected and protected against water jets from all directions |

| GPS | Embedded GPS / GLONASS receiver |

| Operating System | Linux® Cloud enabled with user fleet manager capability |

| Data Stoarge | microSD™ slot with removable 1 GB industrial SD card included |

| USB | (2) USB 2.0 type A host ports for accessories such as wireless LAN, Bluetooth®, and USB flash drives. (1) USB 2.0 type mini-B port for connection to computer. |

| Wireless LAN | Supports 802.11 b/g/n (2.4 GHz) cable optional USB adaptor |

| Bluetooth | Supports Bluetooth® with an optional USB adapto |

| Aiming Camera | Full VGA CMOS camera (Optional on M, C, and L series) |

| Panoramic Camera | 5-megapixel CMOS camera with autofocus lens (Optional on M, C, and L series) |

Vanta Specifications

| Dimensions (W × H × D) | 8.3 cm × 28.9 cm × 24.2 cm (3.25 in. × 11.4 in. × 9.5 in.) |

| Weight | L series: 1.70 kg (3.75 lb) with battery, 1.48 kg (3.24 lb) without battery |

| Excitation Source | (W) and Element (W): 35 kV (2 watts) |

| Primary Beam Filtration | L series and Element: Fixed aluminum filter and no internal collimation |

| Detector | L series and Element: Silicon PIN detector |

| Power | Removable 14.4 V Li-ion battery with hot-swap capability (M, C, and L series only) or 18 V power transformer 100–240 VAC, 50–60 Hz, 70 W max |

| Display | 800 × 480 (WVGA) LCD with capacitive touch screen supporting gesture control |

| Operating evnerionment | Temperature range for the M, C, and L series: −10 °C to 50 °C (14 °F to 122 °F), (continuous duty cycle with optional fan); Temperature range for the Element: −10 °C to 45 °C (14 °F to 113 °F) Humidity: 10% to 90% relative humidity non-condensing |

| Drop Test | Military Standard 810-G 4-foot (1.3 M) drop test |

| IP rating and Detector Shutter | IP55: dust protected and protected against water jets from all directions |

| GPS | Embedded GPS / GLONASS receiver |

| Operating System | Linux® Cloud enabled with user fleet manager capability |

| Data Stoarge | microSD™ slot with removable 1 GB industrial SD card included |

| USB | (2) USB 2.0 type A host ports for accessories such as wireless LAN, Bluetooth®, and USB flash drives. (1) USB 2.0 type mini-B port for connection to computer. |

| Wireless LAN | Supports 802.11 b/g/n (2.4 GHz) cable optional USB adaptor |

| Bluetooth | Supports Bluetooth® with an optional USB adapto |

| Aiming Camera | Full VGA CMOS camera (Optional on M, C, and L series) |

| Panoramic Camera | 5-megapixel CMOS camera with autofocus lens (Optional on M, C, and L series) |

Include :

- Olympus Vanta L Series XRF Analyzer (BC# -L/T*)

- Battery Pack

- Power Cord

- User Manual On Cd-ROM

- Carrying Case (G)

Includes:

- Olympus Omniscan MX2 16:128 Phased Array Ultrasonic Flaw Detector (16:128 Module)

- Battery

- Charger

- Accessory Cable

- Owners Manual

- Hard Case

Nondestructive testing inspectors working in high portability industries require a lightweight, capable equipment. The EPOCH 6LT flaw detector has a small, ergonomic design yet has all of the core functionality of the popular EPOCH 650 flaw detector. Comfortable and easy to use, the EPOCH 6LT flaw detector is small enough to fit into a bag with other equipment. When you’re on the move, the EPOCH 6LT flaw detector for high portability applications has features that help you do your job quickly and efficiently while remaining comfortable.

Designed for Ultra-High Portability

Weighs just 1.95 pounds (890 g) with a grip-oriented weight distribution for one-handed operation with minimal wrist fatigue

Rotary knob and simple button design make it easy to use, even when wearing gloves

Clear, bright screen for readable A-scans in any light

Engineered to IP65/67 and drop tested

The user interface is optimized for single-handed operation. Make adjustments in full A-scan mode using contextual menus, and easily load stored setups using the Quick Recall function for rapid application transitions.

When your inspection is finished, the EPOCH 6LT flaw detector makes data management easy. Multiple report and data file formats can be exported from the instrument via removable USB memory, or with optional Wireless LAN, to the Olympus Scientific Cloud. Take advantage of the instrument’s data management features, including:

- Export calibration, incremental, and 2D data file formats

- Thickness survey export in .CSV format

- Transmit and archive inspection data wirelessly

- Rapid, remote access to inspection data via the Olympus Scientific Cloud

In-Service Pipeline Inspections

The EPOCH 6LT flaw detector is light and ergonomic, making it a good choice for in-service pipeline inspections. The instrument includes flaw sizing software, such as dynamic DAC/TCG and DGS/AVG for weld and crack sizing inspections, as well as optional corrosion software for efficient and precise pipeline corrosion inspections.

Features for In-Service Pipeline Inspections

The EPOCH 6LT flaw detector features an improved corrosion software option, including:

Automatic probe recognition and configuration with center pin ID

Dynamic toggle between flaw scanning and high precision spot measurement modes

Automatic Gain Control (AGC)

Thickness gage high precision measurement algorithm

Automatic zero function (“Do Zero”)

Grid view for data visualization

The EPOCH 6LT flaw detector features the same high dynamic range pulser/receiver as the EPOCH 650 flaw detector, including:

PerfectSquareTM tunable square wave pulser

Digital high dynamic range receiver

Eight (8) 100% digital filter sets

Pulser voltage from 100 V to 400 V

Five customizable digital measurements

Standard Flaw Sizing Software

- Dynamic DAC/TCG: Compares signal amplitude to a DAC curve or reference echo amplitude; the DAC version includes standard, custom DAC warning curves, and 20-80% views

- DGS/AVG: Compares signal amplitude to a DGS/AVG diagram, which illustrates the relationship between echo height, flaw size, and distance from the transducer.

In-Service Rail Inspections

Rail inspectors are frequently on the move and require inspection technology that brings results without the hassle of a heavy, complicated instrument. The intuitive user interface of the EPOCH 6LT flaw detector enables fast and effective flaw detection and prove-up of defects in a highly portable and rugged case design. This combination is ideal for the challenging environment of the rail inspection market.

Features for In-Service Rail Inspections

The EPOCH 6LT flaw detector features the same high dynamic range pulser/receiver as the EPOCH 650 flaw detector, including:

- PerfectSquareTM tunable square wave pulser

- Digital high dynamic range receiver

- Eight (8) 100% digital filter sets

- Pulser voltage from 100 V to 400 V

- Five customizable digital measurements

Aircraft Maintenance Inspections

Aircraft NDT inspectors are often expected to utilize multiple nondestructive testing disciplines in their inspection, such as eddy current or remote video, in addition to ultrasound. The EPOCH 6LT flaw detector is durable, compact, and easily fits in a bag with other equipment. The user interface is intuitive, so even if you don’t operate ultrasonic flaw detectors regularly, you can be confident in your inspection results. Since many newer aircraft skins and components are constructed with difficult-to-inspect composite materials, the EPOCH 6LT flaw detector includes the pulser power and signal-to-noise ratio necessary to solve these challenging applications.

Features for Aircraft Maintenance Inspections

The EPOCH 6LT flaw detector features the same high dynamic range pulser/receiver as the EPOCH 650 flaw detector, including:

-PerfectSquareTM tunable square wave pulser

-Digital high dynamic range receiver

-Eight (8) 100% digital filter sets

-Pulser voltage from 100 V to 400 V

-Five customizable digital measurements

Standard Flaw Sizing Software

Dynamic DAC/TCG: Compares signal amplitude to a DAC curve or reference echo amplitude; the DAC version includes standard, custom DAC warning curves, and 20-80% views